Reel & Line Monitoring System for Cables

Comprehensive Inspection for Armored Cable Manufacturing

The Environmental Machine Vision System (EMVS) by CORPEX is designed to provide complete visual inspection and monitoring in cable manufacturing environments. It identifies missing armor, distorted products, and irregular shapes in real time while improving workplace safety through human detection in the workspace.

EMVS enhances process visibility, quality control, and safety across production lines, helping manufacturers meet the highest standards of precision and efficiency.

Core Features

Real-time

inspection and image analysis for armored cable products

Detection

of missing armor, deformation, and product distortion

Human detection

for enhanced operational safety

Integration with

PLC, SCADA, MES, and OPC systems

Live data exchange

with CMVS for synchronized performance and analysis

Fully configurable

user interface with 19.5-inch touchscreen display

How EMVS Works?

EMVS uses advanced vision and AI algorithms to monitor the cable surface, armor structure, and reel conditions in real time. The system compares live visual data to reference parameters and displays any variations on the operator interface.

Its real-time visualization and recording features allow engineers to analyze production data, identify trends, and take corrective actions before defects propagate through the process.

Applications

• Armored cable inspection

• Reel monitoring and tracking

• Process safety and human detection

• Integration with CMVS for combined quality management

Product Range

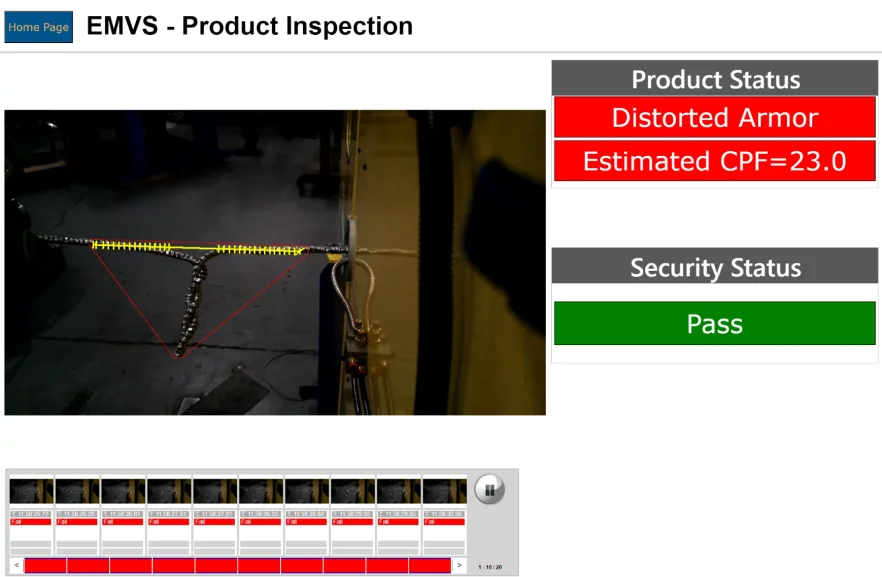

EMVS Product Inspection

Detects missing armor

Detects distorted product

Provides a rough estimate of convolution alignment with specifications

Detects missing product

Identifies misformed armor

Detects a person in the workspace for safety alerts

Fully configurable system parameters

OPC output for system integration

Interfaces with CMVS for measurement, product information, and real-time data exchange

Includes a 19.5-inch touchscreen with a user-friendly display

Optional Thermo Inspection Module:

Detects thermal changes and trends

Monitors product temperature to identify abnormal operating conditions

Provides early detection of lubrication issues

Identifies early signs of tool degradation

Detects incorrect tool or setting selections before production impact

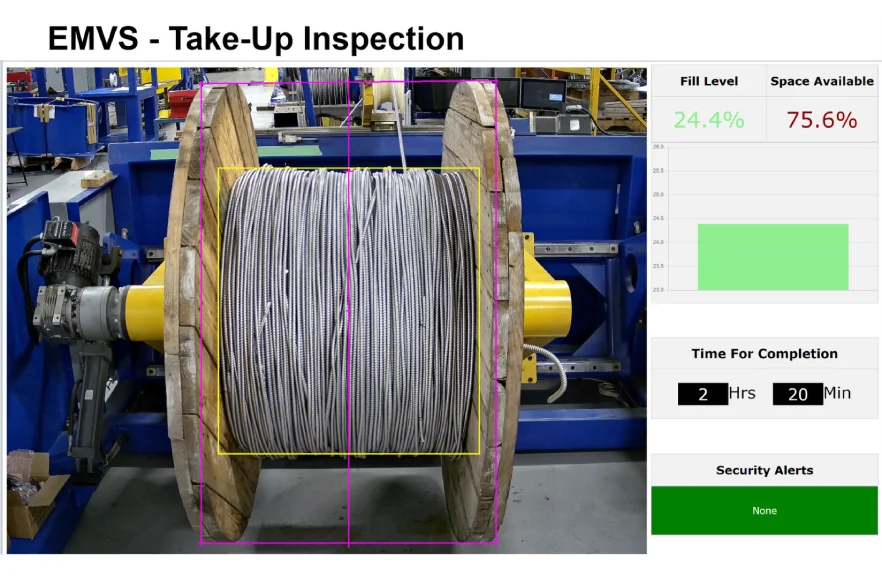

EMVS Reel Inspection

Take-Up and Pay-Off Spool

Detects reel presence and reel sizing

Calculates rate of change to estimate time-to-full or time-to-empty

Detects a person in the workspace for safety monitoring

Fully configurable settings and thresholds

OPC output for integration with plant systems

Interfaces with CMVS for shared measurement data and real-time synchronization

Includes a 19.5-inch touchscreen with a user-friendly display

Industry 4.0 Ready

EMVS is built to integrate seamlessly into Industry 4.0 environments. Through OPC and data connectivity, it becomes part of a fully connected smart inspection ecosystem, providing actionable data for both process optimization and predictive maintenance.

SHARE ON SOCIAL MEDIA

DOWNLOAD THE PDF FILE FOR CABLE & WIRE MANUFACTURING

SHARE ON SOCIAL MEDIA

DOWNLOAD THE PDF FILE FOR CABLE & WIRE MANUFACTURING