Thermo Inspection System

AI-Enhanced Thermal Analysis for Production and Logistics

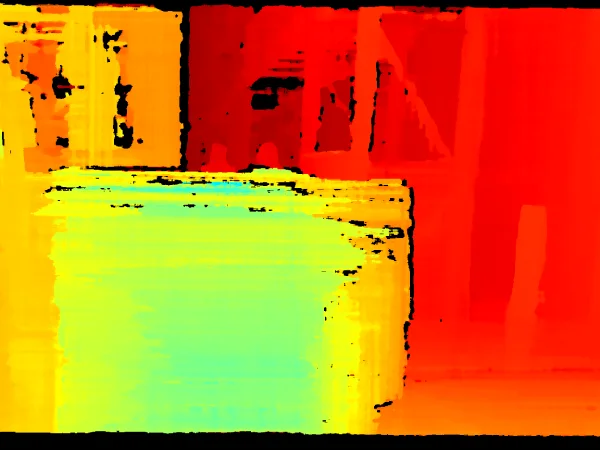

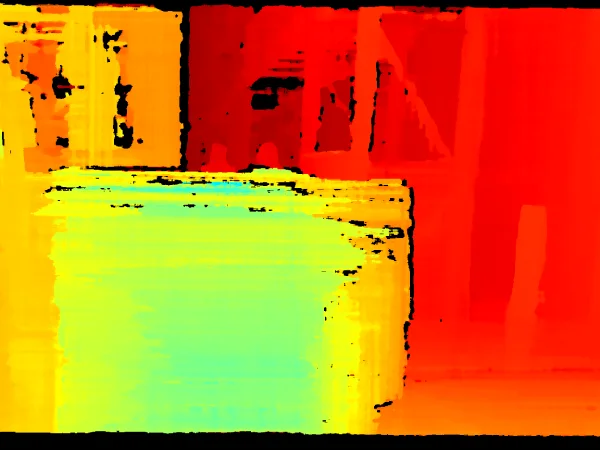

The CORPEX Thermo Inspection System delivers real-time, AI-powered thermal monitoring for manufacturing, warehousing, and logistics environments. It provides full-field temperature visibility across thousands of measurement points, detecting anomalies, equipment issues, or storage problems before they impact quality.

Unlike single-point sensors, this system captures a complete thermal profile of materials, pallets, and production lines, creating a continuous, automated record for quality assurance and traceability

Core Features

Full-Field Thermal Imaging

Captures over 49,000 temperature points per frame at 20 frames per second for complete coverage

AI-Based Pattern Recognition

Identifies subtle heat trends and anomalies related to tool wear, lubrication issues, or thermal leaks

Real-Time Alerts and Visualization

Provides live temperature mapping and triggers alerts for out-of-range zones or uneven cooling

Process and Pallet Monitoring

Inspects both production processes and palletized goods for uniform temperature control

Data Logging and ERP Integration

Records and stores thermal data for performance tracking, reporting, and compliance audits

Seamless System Integration

Connects with PLC, SCADA, MES, and ERP systems for centralized monitoring and automated responses

How the System Works?

The Thermo Inspection System uses high-resolution infrared imaging to continuously analyze heat distribution. AI-driven algorithms interpret temperature variations, detecting deviations such as excessive heating, uneven cooling, or tool degradation.

If temperature patterns shift outside normal ranges, the system issues alerts and displays thermal maps on a 19.5-inch touchscreen for real-time operator response.

All inspection data is archived for long-term trend analysis, predictive maintenance, and verification of temperature compliance.

Technology and Capabilities

• 49,000+ temperature measurement points per frame

• 20 frames per second for live thermal analysis

• Spatial and temporal pattern detection for predictive diagnostics

• AI-enhanced trend learning for proactive maintenance

• Integration-ready for Industry 4.0 systems and smart factories

Thermo Inspection System

Benefits

• Complete thermal visibility across products and materials

• Early detection of temperature-based inefficiencies or defects

• Reduced downtime through predictive alerts

• Higher process consistency and product safety

• Fully traceable thermal records for compliance and auditing

• Eliminates human error from manual measurement

Applications

In Warehousing and Logistics

• 100% pallet inspection at loading docks and storage zones

• Monitoring of incoming and outgoing goods for temperature stability

• Identification of uneven cooling, blocked airflow, or thermal leaks

• Elimination of manual thermometer checks through full automation

In Manufacturing and Production

• Real-time temperature trend detection for tool wear or lubrication failure

• Monitoring of cable, extrusion, or forming lines for abnormal heating

• Early identification of process drift or incorrect machine setup

• Data-based feedback to improve equipment reliability

Thermo Inspection System

Benefits

• Complete thermal visibility across products and materials

• Early detection of temperature-based inefficiencies or defects

• Reduced downtime through predictive alerts

• Higher process consistency and product safety

• Fully traceable thermal records for compliance and auditing

• Eliminates human error from manual measurement

Applications

In Warehousing and Logistics

• 100% pallet inspection at loading docks and storage zones

• Monitoring of incoming and outgoing goods for temperature stability

• Identification of uneven cooling, blocked airflow, or thermal leaks

• Elimination of manual thermometer checks through full automation

In Manufacturing and Production

• Real-time temperature trend detection for tool wear or lubrication failure

• Monitoring of cable, extrusion, or forming lines for abnormal heating

• Early identification of process drift or incorrect machine setup

• Data-based feedback to improve equipment reliability

Industry 4.0 Ready

Thermo Inspection supports full Industry 4.0 environments by connecting to existing automation systems. Its AI-powered analytics transform thermal data into actionable insight, supporting continuous improvement and predictive maintenance.

When combined with other CORPEX vision systems, such as EMVS, Bottle Inspection, and Object Detection, it forms a complete intelligent inspection network across both production and logistics

SHARE ON SOCIAL MEDIA