In cable and wire production, precision is everything. A minor deviation in outside diameter, pitch, or armor quality can lead to costly rework, wasted material, and supply chain delays. Traditional methods rely on manual checks every 30 minutes or more, leaving room for defects to run unnoticed for extended periods.

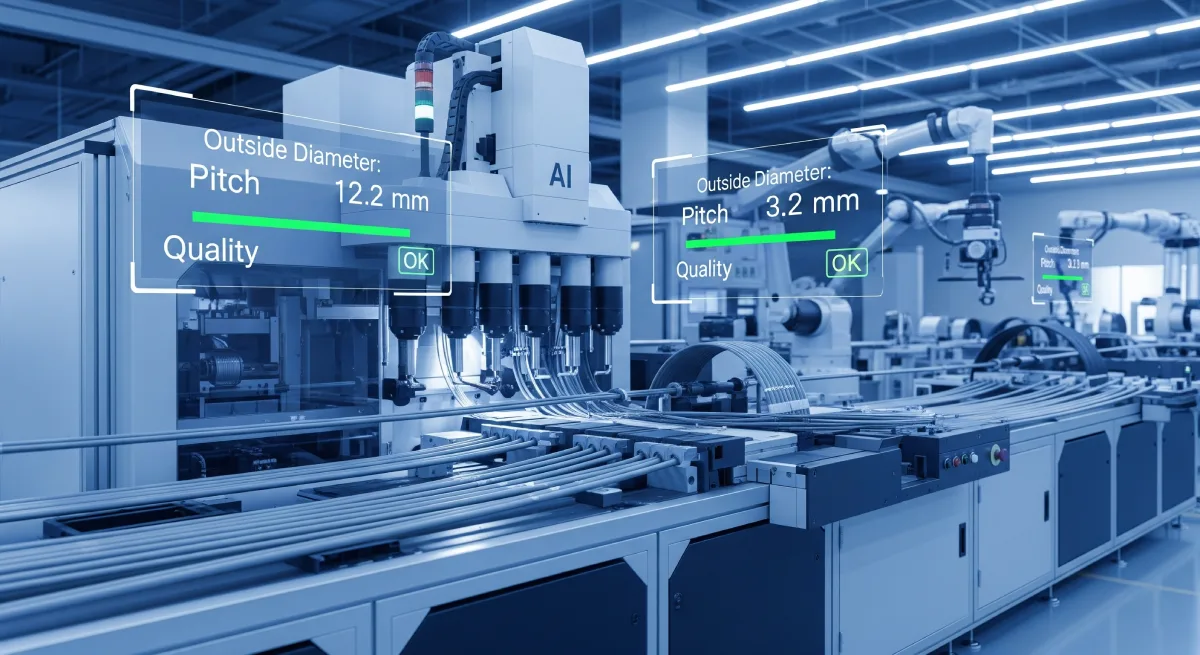

At CORPEX, we solve this challenge with AI-powered machine vision systems that see, measure, and react in real time. Our CMVS (Convoluted Measuring Vision System) is designed specifically for cable armor and copper taping applications, offering unmatched accuracy and speed for today’s high-demand production lines.

Real-Time Intelligence on the Factory Floor

Unlike conventional sensors, our solutions provide a live interface with PLCs and SCADA systems, allowing automatic corrections without operator intervention. Dimensional issues are caught immediately; not half an hour later. The result:

- Reduced scrap and rework

- Lower material waste

- Improved product consistency and quality

By publishing inspection data and building image libraries of failures, CORPEX also helps quality teams analyze trends, refine processes, and ensure compliance.

Why It Matters for Cable & Wire Manufacturers

The industry has long faced a gap: sophisticated robotics and smart inspection systems were common in automotive and aerospace, but cable and wire plants often lacked access to this level of technology. CORPEX bridges that gap, bringing Industry 4.0 intelligence directly into wire production.

Whether it’s armored cables, copper taping, or re-spooling operations, our systems ensure that production is not only faster, but smarter.

Learn More & Connect

Discover how CORPEX is helping cable and wire manufacturers achieve greater accuracy, sustainability, and profitability. Visit our homepage to explore our solutions, or follow us on LinkedIn for insights and updates.