If you have ever watched a production line and wondered how manufacturers maintain such high quality at full speed, the answer often comes down to machine vision. Machine vision gives a system the ability to see what is happening in real time and make decisions based on what it detects.

At CORPEX, machine vision is the foundation of our technology. What truly sets CORPEX apart is how we combine Machine Vision and AI into one powerful, integrated solution. This hybrid approach gives manufacturers accuracy, speed, and reliability that traditional vision tools cannot match.

What Is Machine Vision?

Machine vision is technology that allows industrial systems to visually inspect, measure, and analyze products during production. It works like the eyes of your factory, using cameras and sensors to instantly check for:

- Dimensions

- Defects

- Presence or absence of components

- Real time product deviations

- Position and orientation

The goal is simple. Detect issues early, improve quality, reduce scrap, and eliminate time-consuming manual inspection.

CORPEX systems such as CMVS and EMVS do exactly this. For example, CMVS measures OD, pitch, and product length with extremely high accuracy at speeds up to 80 ft per minute. It alerts operators instantly or even adjusts the machine automatically. It also publishes data to OPC and SCADA and builds an image library for QC analysis .

Why Machine Vision Alone Is No Longer Enough

Traditional vision systems can detect something unusual, but they cannot always understand what it is. They can produce false positives that stop production unnecessarily or false negatives that let defective product pass.

CORPEX solves this by pairing machine vision with advanced AI.

How CORPEX Uses AI to Improve Machine Vision

Instead of relying on a single technology, CORPEX combines both AI and Machine Vision in a stacked hybrid approach. This is what gives CORPEX systems their next-level intelligence and reliability.

What AI Adds to the Equation

AI allows the system to:

- Recognize patterns that traditional vision cannot

- Distinguish real defects from harmless variations

- Predict failures or abnormal behavior

- Make smarter decisions based on context

This combination is especially important in applications like puckering detection. Machine vision identifies visual irregularities on the cable. AI analyzes those irregularities to determine whether they represent a real defect. This eliminates both false positives and false negatives, reducing downtime and improving product quality.

Your documentation states it clearly:

“AI or machine vision cannot solve the issue. They have to work together. With this combination we are able to solve the problem since we use stacking technology.”

This is exactly what CORPEX delivers.

Where CORPEX Uses Machine Vision and AI Today

CORPEX integrates hybrid AI and vision systems across the full production environment.

1. CMVS for Cable and Wire Measurement

Real time measurement of OD, convolution pitch, and product length, with live PLC feedback, smart alerts, QC image storage, and multiple configuration sizes for OD ranges from 0.15 inches to 5.0 inches .

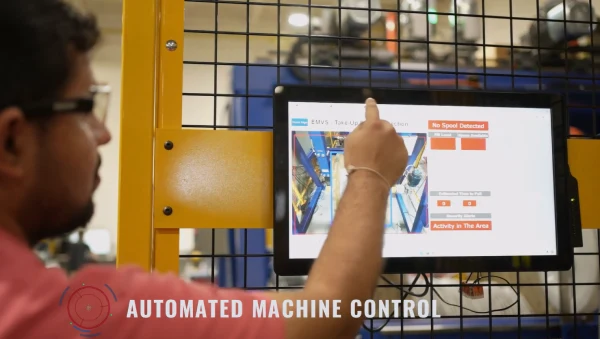

2. EMVS for Environmental and Product Inspection

Detects missing armor, distorted product, miss-formed armor, missing material, or people in the workspace. Includes optional Thermo Inspection for early detection of lubrication issues, tool wear, temperature changes, or incorrect machine settings .

3. Puckering Detection

A fully hybrid solution that uses stacked AI and Machine Vision technology to detect armor defects and eliminate both false positives and false negatives. This is a long-standing industry problem that CORPEX solves reliably with its unique approach .

4. Solutions for Logistics and Bottling

Under CORPEX Solutions, AI enhanced vision monitors:

- Bottle fill level and seal closure

- Pallet fullness and pallet damage

- Human presence for safety

- Label accuracy with OCR and QR verification

- Temperature changes in logistics

All in real time and fully designed to reduce waste and human error while improving speed and productivity .

Why AI Enhanced Vision Matters for Today’s Manufacturers

Many production lines rely on fixed interval manual checks. If a defect appears right after a manual check, the machine may continue producing out of spec product for 30 minutes or longer. This leads to scrap, rework, rewinding, downtime, and extra material consumption.

CORPEX gives factories real time insight instead of delayed discovery. With continuous inspection, live feedback, predictive insight, and direct Industry 4.0 integration, CORPEX transforms your production from reactive to proactive.

CORPEX: 30 Plus Years of Proven Machine Vision Expertise

With more than three decades of hands-on experience in Machine Vision and AI for industrial environments, CORPEX has built a reputation for delivering reliable, high performance inspection systems. Our technologies are trusted across cable and wire manufacturing, bottling, logistics, and other production environments where accuracy, uptime, and waste reduction truly matter.

Whether you want to reduce scrap, eliminate defects, improve safety, or modernize your operation with Industry 4.0 capabilities, CORPEX gives you the real time insight and control needed to run smarter and more efficiently.

Want to explore how CORPEX can improve your production line?

We would be happy to help you choose the right CORPEX solution for your needs.

You can reach CORPEX directly at:

📞 +1 416 358 0005

📧 getinfo@corpex.biz

🌐 www.corpex.biz/contact , LinkedIn