Label Inspection System

AI-Driven Accuracy for Product Identification and Compliance

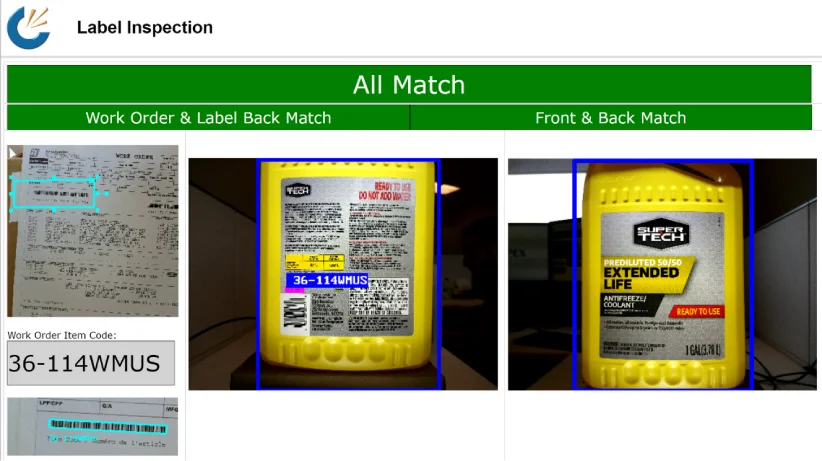

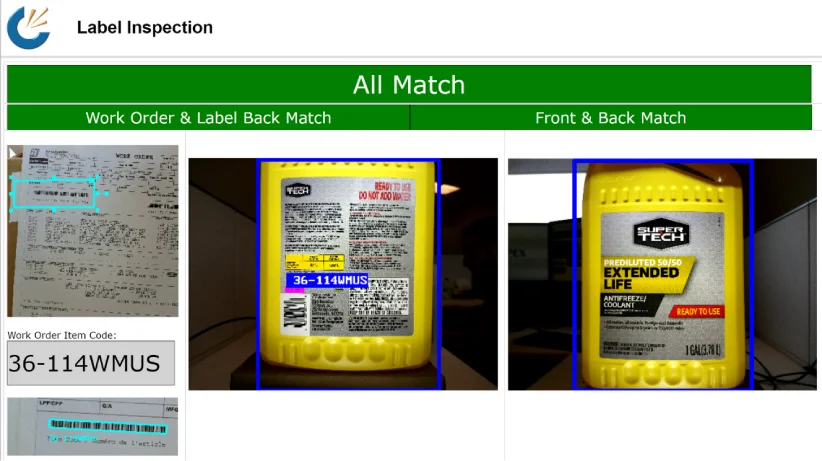

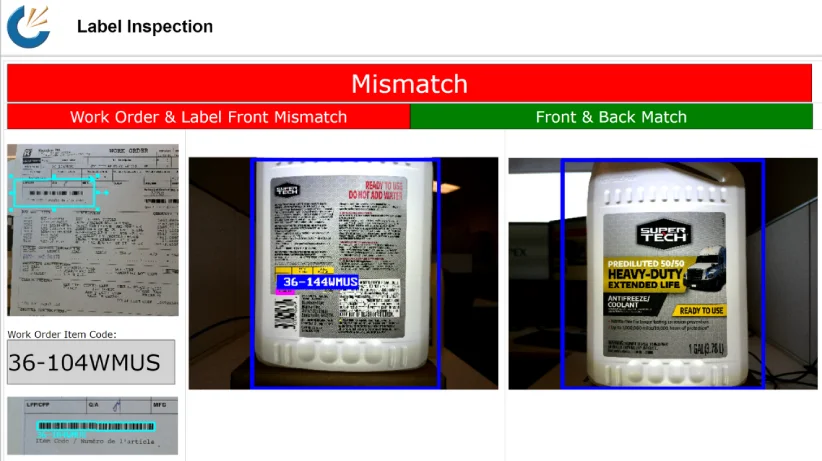

The CORPEX Label Inspection System ensures every product label is present, correct, and properly positioned. Using advanced machine vision and AI recognition, it verifies label accuracy, alignment, and readability in real time.

By checking every container as it moves through production, the system prevents labeling errors, reduces waste, and maintains full compliance with product traceability and branding standards.

Core Features

Label Presence and Position Verification

Confirms each label or sleeve is applied, straight, and within placement tolerances

OCR and Barcode Reading

Reads printed data, QR codes, and serial numbers for traceability and work order validation

Label-to-Work Order Match

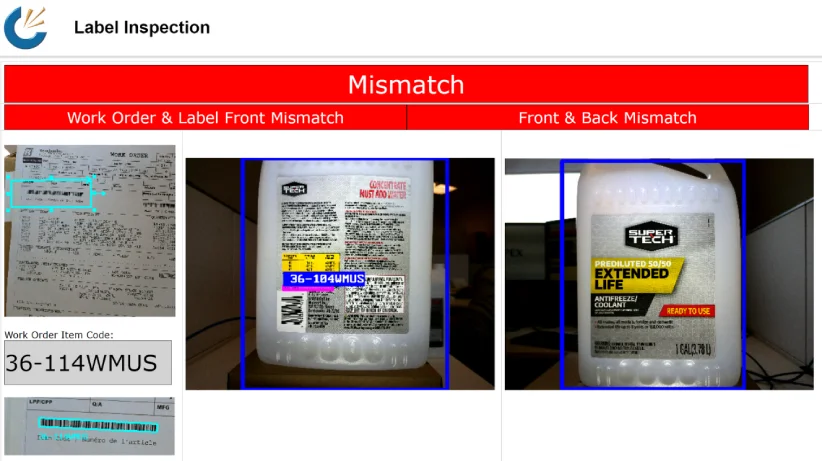

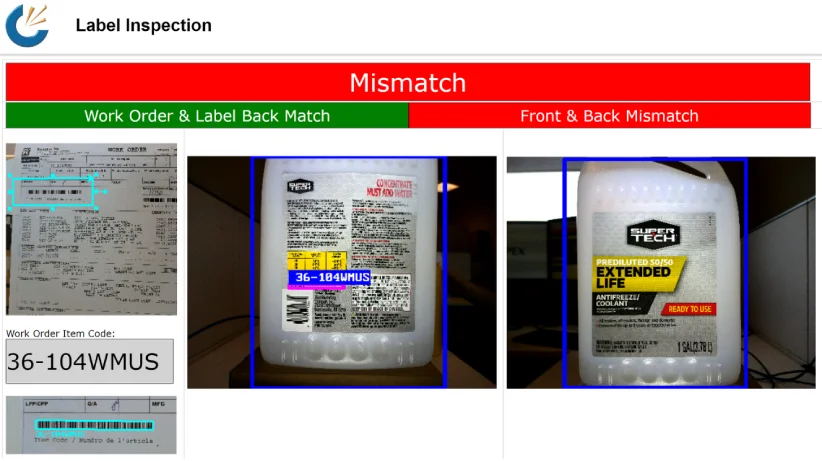

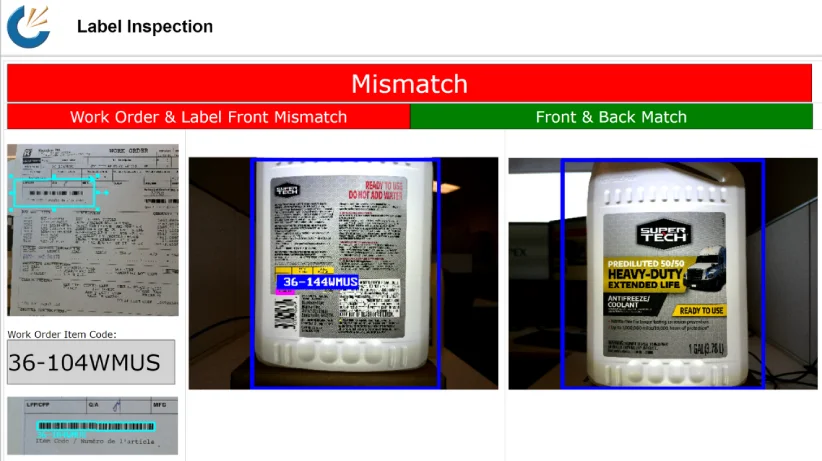

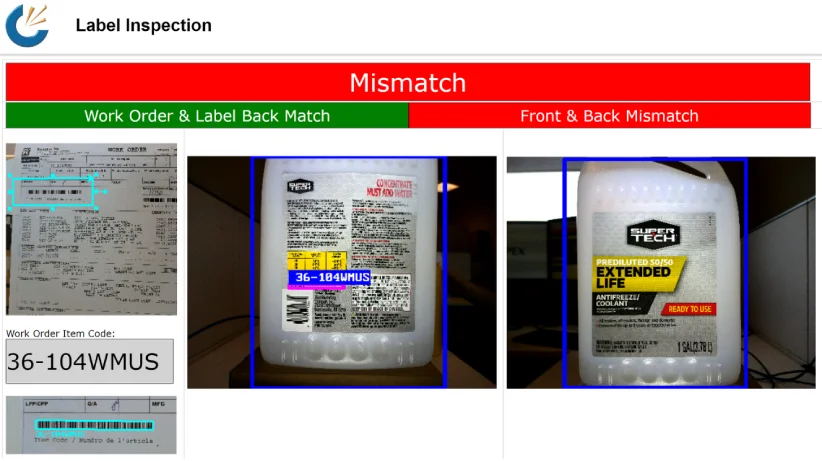

Compares label content to active production work order using AI-based text verification

Defect and Mismatch Detection

Detects missing, skewed, duplicate, or incorrect labels to prevent packaging errors

Integration with Factory Systems

Connects with SCADA, MES, and PLC systems for data logging, alarms, and process reporting

User Interface and Data Storage

Large touchscreen for live monitoring, with full image and record archiving for audits and quality review

How the System Works?

The system uses high-resolution cameras and OCR algorithms to inspect each label in motion. AI-based software compares detected text and codes against predefined work order information to ensure the correct label is used.

It also measures alignment and placement on the container, providing alerts if the label is missing, crooked, or applied on the wrong SKU.

Each inspection event is logged, providing a complete record for traceability and production validation.

Data Validation and Traceability

CORPEX Label Inspection integrates Optical Character Recognition (OCR) and barcode verification to validate every printed element.

• Verifies batch codes, serial numbers, and product identifiers.

• Ensures QR codes and barcodes are readable and accurate.

• Prevents label duplication or use of outdated artwork.

This verification guarantees that all packaging information is correct before shipment, ensuring compliance with regulatory and customer standards

Label Inspection System

Benefits

• 100% label inspection at full line speed

• Prevents incorrect or misplaced labels

• Reduces rework, recalls, and product waste

• Ensures SKU and batch traceability through OCR and barcode reading

• Provides archived images for audit and regulatory compliance

• Enhances accuracy and consistency in labeling operations

Applications

• Food, beverage, and consumer goods packaging

• Chemical and industrial labeling processes

• Pharmaceutical and healthcare product lines

• Bottling and labeling environments with mixed SKUs

Benefits

• 100% label inspection at full line speed

• Prevents incorrect or misplaced labels

• Reduces rework, recalls, and product waste

• Ensures SKU and batch traceability through OCR and barcode reading

• Provides archived images for audit and regulatory compliance

• Enhances accuracy and consistency in labeling operations

Applications

• Food, beverage, and consumer goods packaging

• Chemical and industrial labeling processes

• Pharmaceutical and healthcare product lines

• Bottling and labeling environments with mixed SKUs

Industry 4.0 Ready

The Label Inspection System supports full Industry 4.0 connectivity.

Data is transferred via OPC, SCADA, and MES systems, providing instant visibility into labeling accuracy and system health.

When combined with the CORPEX Bottle Inspection or Object Detection Systems, it forms part of a complete, intelligent quality assurance ecosystem that safeguards both product accuracy and brand integrity

SHARE ON SOCIAL MEDIA

DOWNLOAD THE PDF FILE FOR BOTTLE INSPECTION SYSTEM

SHARE ON SOCIAL MEDIA

DOWNLOAD THE PDF FILE FOR BOTTLE INSPECTION SYSTEM