FAQ

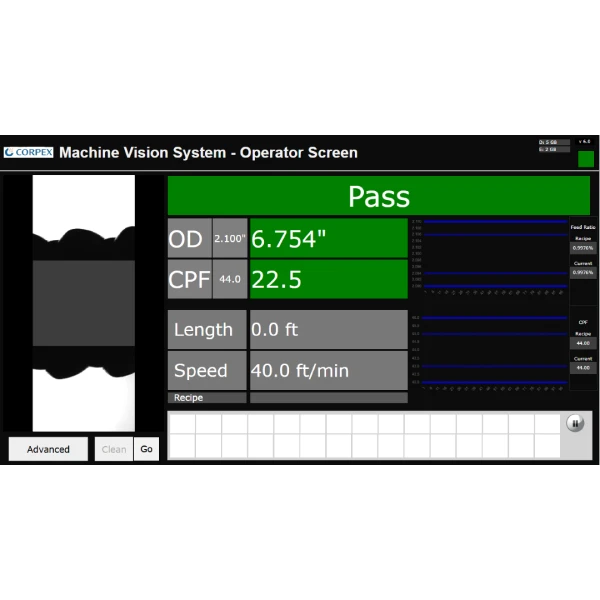

The CMVS (Cable Measuring Vision System) uses AI-powered machine vision to measure key product specifications such as outside diameter, convolution pitch, and length in real time. It detects dimensional failures instantly and communicates with your PLC to auto-adjust production without operator action. This prevents scrap, reduces downtime, and improves consistency.

CORPEX offers multiple CMVS models to match different cable sizes and production needs:

- CMVS 35 – Measures 0.15″ to 1.35″ OD with ±0.001″ accuracy at speeds up to 80 ft/min. Max pitch 0.65″ or 18 CPF.

- CMVS 55 – Measures 0.25″ to 2.2″ OD with ±0.002″ accuracy. Max pitch 0.75″ or 16 CPF.

- CMVS 100 – Measures 0.25″ to 4.0″ OD with ±0.002″ accuracy.

- CMVS 125 – Measures 0.25″ to 5.0″ OD with ±0.002″ accuracy.

- CMVS 125 Dual Axis – For flat products like control cable, measuring 1.5″ to 5.0″ width and 0.24″ to 1.25″ height.

All models feature high-speed real-time inspection, flexible mounting, a 19.5″ touchscreen HMI, and optional smart stack lights.

Depending on configuration, CMVS systems deliver real-time accuracy as high as ±0.001 inches at maximum production speeds of up to 80 feet per minute. They support a wide range of product sizes and can be customized for both round and flat cables.

The EMVS (Environmental Machine Vision System) inspects products for defects like missing or malformed armor, missing product sections, or distorted shapes. It also detects human presence in hazardous zones, monitors reel size and fill rate, and can integrate thermal inspection for early detection of lubrication issues, tool degradation, or incorrect tooling.

Yes. CORPEX systems detect defects the moment they occur, rather than during scheduled manual checks. This prevents long runs of out-of-spec product, saving material, time, and labor while avoiding the need for rewinding, reinspection, and rescheduling.

No. While our primary focus is cable and wire production, CORPEX systems are also deployed in warehousing, bottling, and other manufacturing environments. Applications include pallet inspection, traffic monitoring, fill-level checks, and label verification.

The CMVS is more than a measuring device. It connects directly to your PLC to read target specifications and automatically adjust production without operator input. It can trigger on-screen alerts or optional smart lights, publish data to OPC/SCADA systems, and store an image library of failed products for quality control. This automation reduces manual checks, eliminates repeated defects, and ensures consistent product quality from the first foot to the last.

Our systems connect directly to PLC, SCADA, and MES platforms, creating a live feedback loop between machines, operators, and management systems. This supports decentralized decision-making, reduces manual intervention, and improves sustainability through reduced waste and energy use.

Thermal inspection detects abnormal temperature changes in products or equipment. This allows for early identification of lubrication problems, tool wear, and potential safety hazards, helping prevent unplanned downtime and improving product quality.

Yes. Our machine vision systems inspect caps and seals for proper closure, verify fill levels in transparent or semi-transparent bottles, and use OCR to confirm that labels match the work order. This prevents costly labeling errors and product recalls.

CORPEX technology uses human detection to identify workers in hazardous zones in real time, triggering alerts to prevent accidents. This is particularly valuable in high-traffic areas like loading docks, warehouse aisles, and production floors.

All inspection results are logged for post-process and inline analysis. Data can be published to OPC/SCADA systems, enabling long-term quality tracking, process optimization, and integration with enterprise resource planning (ERP) systems.

Absolutely. We offer multiple CMVS and EMVS models with different size ranges, accuracy levels, and configurations. Systems can be tailored to your specific product dimensions, speed requirements, and environmental conditions.

By catching defects early and enabling precise process control, our systems reduce material waste, lower energy use, and extend equipment life. This helps clients meet both cost reduction and environmental sustainability goals.

See CORPEX in Action

High-Precision Inspection for Small-Diameter Cable

Engineered for compact applications, CMVS 35 delivers ±0.001″ accuracy in real time. Ideal for fine-gauge armored cable.

Start a Conversation with Our Experts Now

What is next?

01

Analysis & Benchmarking

We begin by assessing your production environment, identifying inefficiencies, and capturing baseline performance data. This ensures we target the right areas for improvement with measurable results.

02

System Design & Configuration

Our engineering team tailors a CORPEX machine vision and AI solution to your exact product sizes, speed requirements, and integration needs. We configure hardware, software, and data connections to your PLC, SCADA, or MES systems for seamless operation.

03

Integration & Optimization

We install and calibrate your system directly on the production floor, provide operator and maintenance training, and enable real-time feedback loops. Continuous monitoring and fine-tuning maximize efficiency, quality, and sustainability from day one.

By Sending this request you agree to our Terms & Conditions and Privacy Policy.

GIVE US A CALL

+1 416 358 0005

SEND US AN EMAIL

getinfo@corpex.biz