Machine Vision for Copper Taping

High-Speed Precision for Cable Taping Inspection

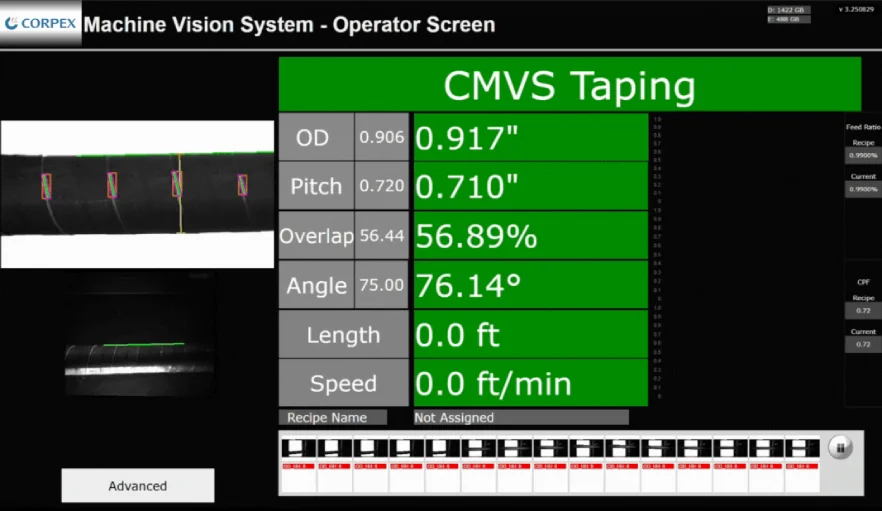

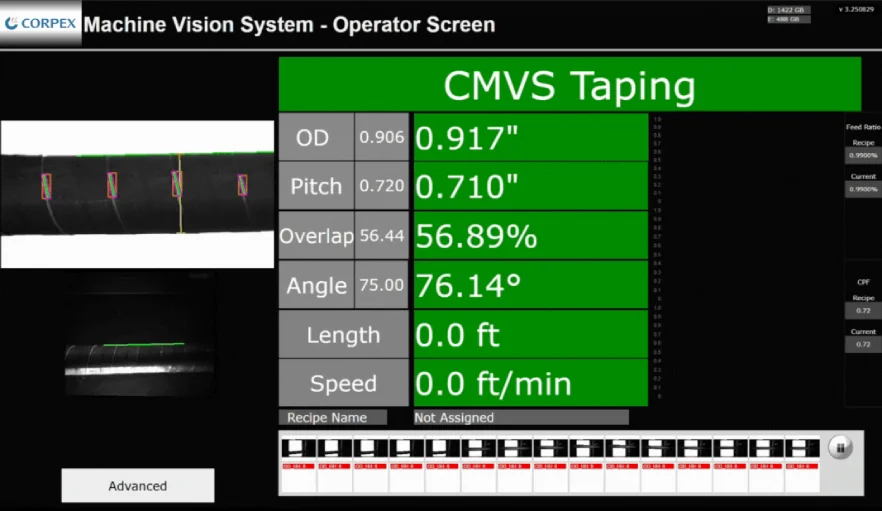

The CORPEX Copper Taping Vision System delivers high-speed, real-time inspection for copper-taped cable production. It measures outside diameter, pitch, and overlap percentage to ensure consistent taping accuracy across every product.

By combining advanced vision sensors with AI analysis, the system detects missing tape, pitch variation, and misalignment as they occur, helping manufacturers maintain precision, reduce rework, and improve overall production quality.

Core Features

Real-time

measurement of outside diameter, pitch, and overlap percentage

Operational

line speeds up to 200 ft/min

Precision

under 1 percent for pitch and overlap

Records and logs

measurement data for analysis and traceability

Detection

of missing, loose, or misaligned tape

Integration

with CMVS, SCADA, MES, and OPC systems

How the Copper Taping Works?

High-resolution imaging captures each revolution of the taping process. The system’s algorithms calculate pitch, overlap, and angle while identifying any deviation from target specifications.

Operators receive immediate visual feedback through the touchscreen interface, while all inspection data is stored for trend tracking and quality reports.

Technical Capabilities

• Product range from 0.25 to 4.0 inches in diameter

• Pitch measurement precision up to 0.006 inches at 3-inch pitch and 0.003 inches up to 1-inch product size

• Real-time failure detection for missing tape or out-of-spec overlap

• Continuous inspection even at maximum line speed

Copper Taping Inspection

Benefits

• Maintains uniform tape overlap and pitch throughout production

• Reduces waste by catching defects early

• Improves line efficiency through data-driven adjustments

• Ensures high-quality, consistent cable output for demanding applications

Applications

• Copper taping for armored and communication cables

• Control cable taping processes

• Real-time quality inspection on high-speed production lines

• Re-spooling and take-up quality verification

Copper Taping Inspection

Benefits

• Maintains uniform tape overlap and pitch throughout production

• Reduces waste by catching defects early

• Improves line efficiency through data-driven adjustments

• Ensures high-quality, consistent cable output for demanding applications

Applications

• Copper taping for armored and communication cables

• Control cable taping processes

• Real-time quality inspection on high-speed production lines

• Re-spooling and take-up quality verification

Industry 4.0 Ready

The Copper Taping Vision System connects seamlessly with other CORPEX inspection technologies, such as CMVS and EMVS, to form a complete Industry 4.0-ready ecosystem.

By integrating with plant systems, it provides measurable process data, quality analytics, and live insight into every stage of cable manufacturing.

SHARE ON SOCIAL MEDIA

DOWNLOAD THE PDF FILE FOR CABLE & WIRE MANUFACTURING