Bottle Inspection System

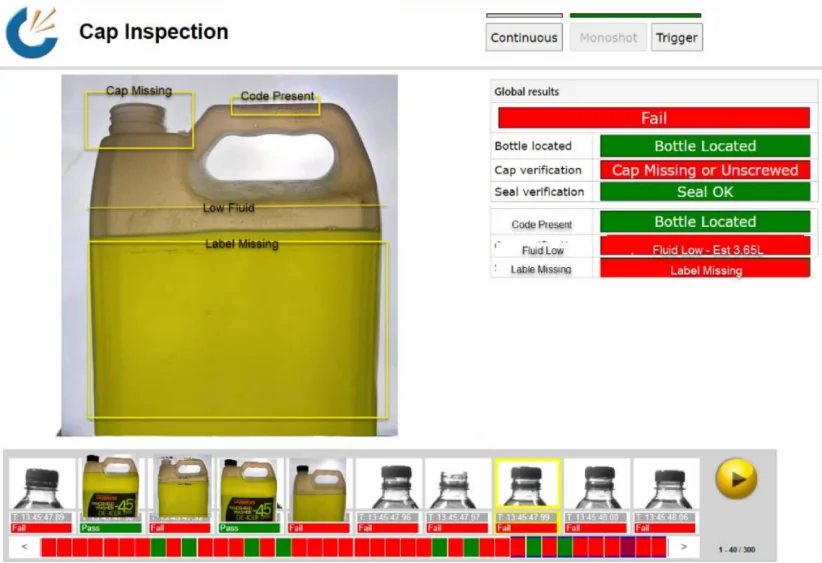

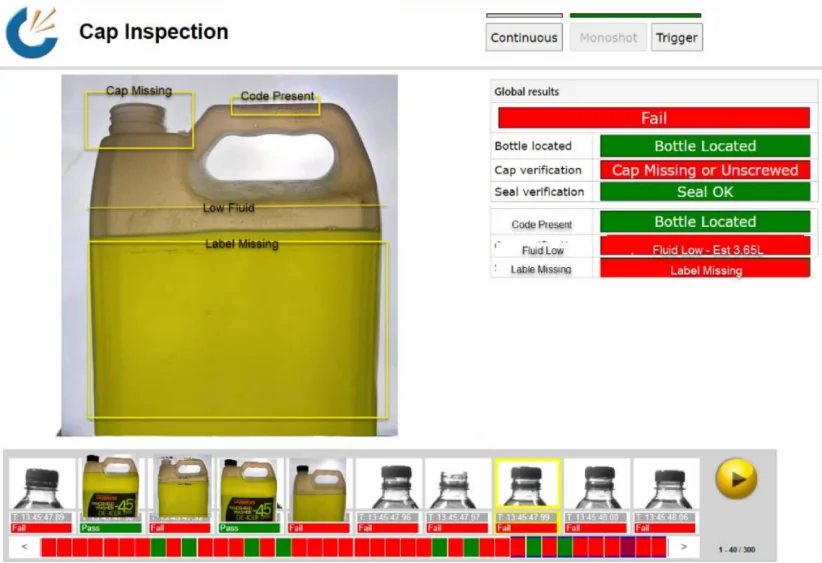

Smart Vision for Fill, Cap, and Label Verification

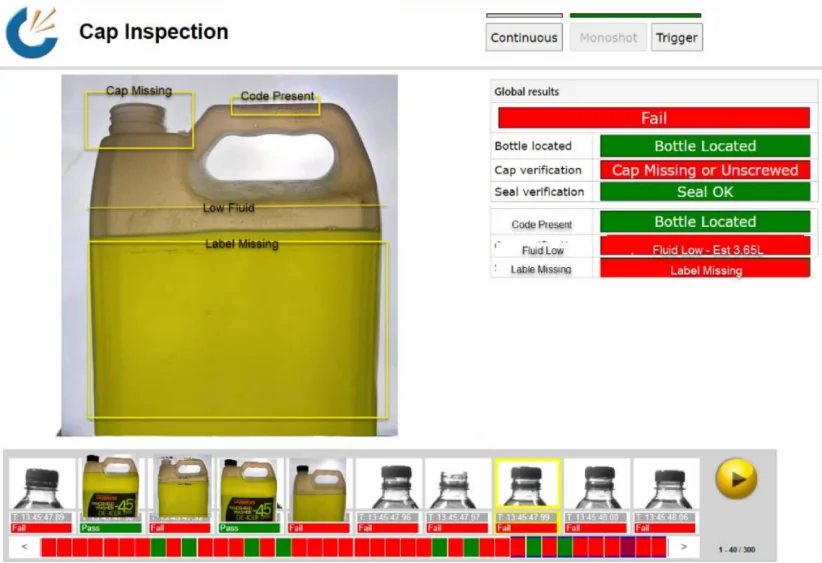

The CORPEX Bottle Inspection System delivers AI-powered vision inspection for bottling and packaging operations. It ensures every bottle meets strict quality standards by detecting missing caps, seal issues, label errors, and fill-level variations in real time.

Engineered for transparent and semi-transparent bottles, the system eliminates manual checks, reduces waste, and improves efficiency across production lines

Core Features

Cap and Seal Verification

Detects missing, tilted, or loose caps and ensures seals are properly aligned

Label Presence and Position

Confirms labels or sleeves are present, straight, and correctly applied on any bottle color

Fill-Level Detection

Uses optical algorithms to measure liquid levels on transparent and light-colored bottles, eliminating weighing

OCR and SKU Validation

Optionally verifies printed codes, batch data, or product SKUs against the work order for labeling accuracy

Integration and Connectivity

Interfaces with PLC, SCADA, MES, and OPC systems for seamless Industry 4.0 data flow

User-Friendly Interface

Large touchscreen for live feedback, configuration, and visual review of rejected items

How the System Works?

Each bottle passes through a high-resolution camera station where AI and vision algorithms assess cap placement, label alignment, and fill level.

When a defect or mismatch is detected, the system triggers an alert or ejects the affected bottle. All results are logged, creating a traceable digital record for analysis and quality assurance.

Inspection Modules

Cap and Seal Inspection:

Ensures cap presence, straightness, and correct placement under defined tolerances. Detects partial or cross-threaded closures.

Label Inspection:

Verifies label or sleeve presence and alignment, with optional OCR or barcode scanning to confirm correct product labeling.

Fill-Level Verification:

Analyzes optical and volumetric data to calculate fill height. Accuracy is achieved through shape and transparency calibration, offering a fast and efficient alternative to weighing-based systems

Bottle Inspection System

Benefits

• 100% in-line, non-contact inspection

• Detects and prevents packaging errors before they leave the line

• Improves throughput and reduces waste

• Provides automatic traceability and batch reports

• Reduces labor and inspection downtime

• Enhances consistency and customer satisfaction

Applications

• Beverage and food bottling lines

• Chemical and lubricant packaging

• Health and pharmaceutical product filling

• Transparent and semi-transparent containers

• Integration with cap, label, and fill-level modules on multi-stage lines

Bottle Inspection System

Benefits

• 100% in-line, non-contact inspection

• Detects and prevents packaging errors before they leave the line

• Improves throughput and reduces waste

• Provides automatic traceability and batch reports

• Reduces labor and inspection downtime

• Enhances consistency and customer satisfaction

Applications

• Beverage and food bottling lines

• Chemical and lubricant packaging

• Health and pharmaceutical product filling

• Transparent and semi-transparent containers

• Integration with cap, label, and fill-level modules on multi-stage lines

Industry 4.0 Ready

The CORPEX Bottle Inspection System connects seamlessly to factory networks through OPC, MES, and SCADA systems.

This integration enables live performance dashboards, predictive maintenance, and data-driven decision-making.

When paired with other CORPEX solutions like Label Inspection or Object Detection, it forms part of a complete smart quality ecosystem

SHARE ON SOCIAL MEDIA

DOWNLOAD THE PDF FILE FOR BOTTLE INSPECTION SYSTEM

SHARE ON SOCIAL MEDIA

DOWNLOAD THE PDF FILE FOR BOTTLE INSPECTION SYSTEM