AI in the wire and cable industry improves product quality, reduces scrap, and enables real-time control by detecting defects and dimensional variation as production happens.

Instead of relying on offline inspection or manual sampling, manufacturers now use AI-powered machine vision systems to monitor every meter of cable at full line speed.

This shift is critical for modern wire and cable manufacturing, where tighter tolerances, higher volumes, and traceability requirements leave no room for delayed feedback.

Why AI Matters in Wire and Cable Manufacturing

Traditional inspection methods only catch problems after material is already produced. By that point, scrap, rework, and downtime are unavoidable.

AI-based machine vision changes this by delivering:

- Continuous inspection at line speed

- Immediate out-of-tolerance alerts

- Consistent measurement without operator variability

- Logged data for audits and quality reporting

CORPEX systems apply AI directly on the production line, allowing operators to correct issues before defects spread across reels or runs

Key AI Applications in the Wire and Cable Industry

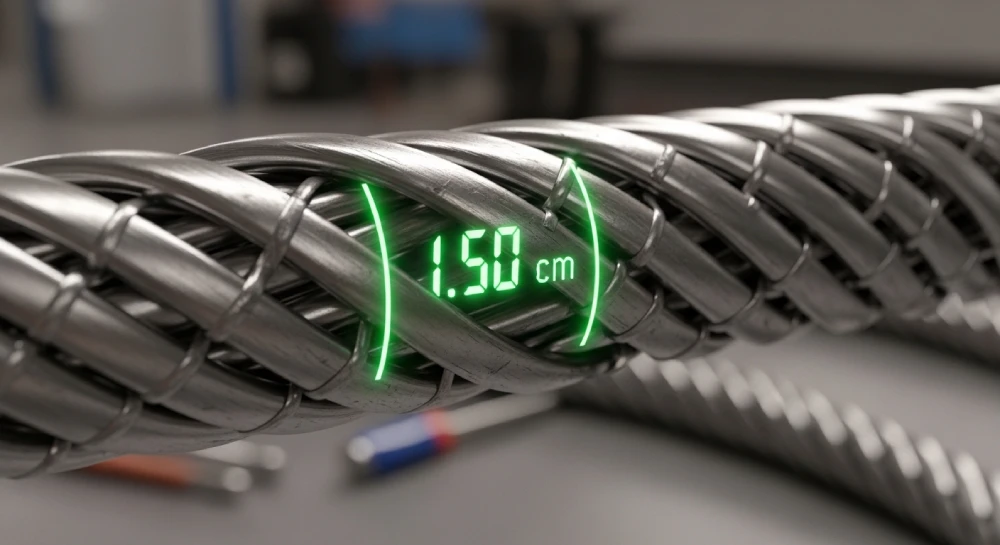

1. Real-Time Diameter and Pitch Measurement

AI vision systems continuously measure outside diameter, pitch, and length during production. This is especially important for armored and convoluted cables where dimensional drift can cause downstream failures.

Learn more about

Machine Vision for Wire & Cable

2. Surface Defect Detection for ESP Cables

AI detects surface defects such as scratches, marks, and irregularities that are difficult to see consistently with the human eye. This is critical for ESP cables used in demanding environments.

Explore

Surface Defect Detection for ESP Cables

3. AI Inspection for Copper Taping

Copper taping requires precise overlap, pitch, and alignment. AI inspects every revolution of the taping process and flags missing tape, misalignment, or loose tape instantly.

See

Machine Vision for Copper Taping

4. Reel and Line Monitoring

AI-driven reel and line monitoring systems ensure consistent winding, tension, and continuity across long production runs, preventing costly reel-level scrap.

View

Reel and Line Monitoring System for Cables

How AI Reduces Scrap and Improves Yield

AI does not just measure. It learns normal process behavior and identifies deviations early.

Benefits include:

- Early detection of dimensional drift

- Fewer out-of-spec reels

- Reduced material waste

- Higher first-pass yield

- Faster root cause analysis using stored data

By connecting AI vision systems directly to PLC, SCADA, MES, and OPC environments, CORPEX enables automated alarms and reporting without slowing production.

AI and Industry 4.0 Readiness

AI-powered inspection is a core pillar of Industry 4.0. CORPEX systems are designed for seamless integration into smart manufacturing environments.

They support:

- Real-time dashboards via integrated HMI

- Recipe and tolerance changes by product

- Data storage for audits and traceability

- Network connectivity for IT and automation systems

Learn more about

Industrial IT & Automation

Choosing the Right AI Vision System

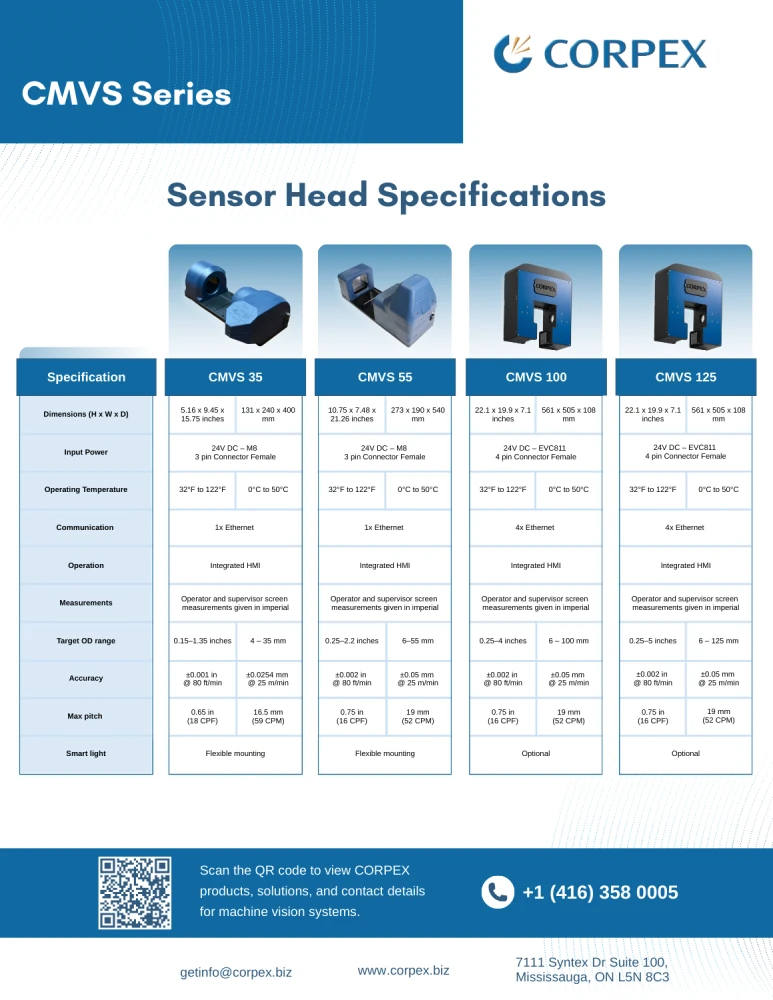

CORPEX offers multiple AI-powered machine vision systems for wire and cable manufacturers, including CMVS 35, CMVS 55, CMVS 100, and CMVS 125. Each system is designed for specific diameter ranges, speeds, and inspection needs.

Start at the CORPEX Home Page or contact the team to match the right system to your production line.

Frequently Asked Questions

What problems does AI solve in the wire and cable industry?

AI solves late defect detection, inconsistent manual inspection, excessive scrap, and lack of production traceability.

Is AI inspection suitable for high-speed production lines?

Yes. CORPEX AI vision systems inspect continuously at full line speed without slowing production.

Can AI systems integrate with existing automation?

Yes. CORPEX systems connect directly to PLC, SCADA, MES, and OPC environments.

Does AI replace operators?

No. AI supports operators by providing instant visibility and actionable alerts so they can maintain quality more effectively.

For more answers, visit the

CORPEX FAQ Page

Who Is CORPEX?

CORPEX is a machine vision and industrial automation company specializing in AI-powered inspection systems for manufacturing. With over 30 years of experience, CORPEX delivers real-time inspection solutions for wire and cable production, copper taping, surface defect detection, and industrial automation.

Learn more

About CORPEX

Contact CORPEX

If you want to improve quality, reduce scrap, and gain real-time control using AI, contact CORPEX today.

Contact Page:

https://www.corpex.biz/contact/

Phone: +1 (416) 358 0005

Email: getinfo@corpex.biz

Address: 7111 Syntex Dr, Suite 100, Mississauga, ON, CA