Machine vision is transforming wire and cable manufacturing by enabling real-time inspection, precise dimensional measurement, early defect detection, and continuous production monitoring without slowing down the line. Modern machine vision systems use high-resolution cameras and AI-driven analytics to measure outside diameter, pitch, length, and surface quality while instantly alerting operators when values drift out of tolerance. This results in lower scrap rates, higher first-pass yield, and consistent product quality across demanding wire and cable applications

Why Traditional Inspection No Longer Works

Wire and cable manufacturers face increasing pressure from tighter tolerances, higher production speeds, and stricter quality standards. Traditional inspection methods rely heavily on manual checks or offline measurements, which introduce several problems:

- Defects are discovered after scrap is already produced

- Inconsistent measurements between operators

- Limited traceability for audits and customer requirements

- Production slowdowns during quality checks

Machine vision eliminates these issues by inspecting every millimeter of cable in real time directly on the production line.

What Is Machine Vision in Wire and Cable Manufacturing

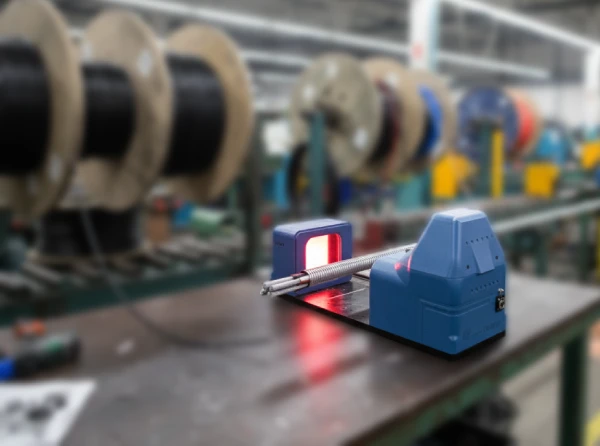

Machine vision systems use industrial cameras, smart lighting, and AI-based software to continuously inspect wire and cable products during manufacturing. These systems are designed to operate at full line speed while delivering highly accurate measurements.

In wire and cable production, machine vision is used to monitor:

- Outside diameter consistency

- Convolution and armor pitch

- Product length and speed

- Copper taping overlap and alignment

- Surface defects on ESP and specialty cables

CORPEX machine vision systems are built specifically for armored, convoluted, and high-speed cable lines, ensuring stable measurement and reporting under industrial conditions

Key Ways Machine Vision Is Transforming Wire and Cable Manufacturing

Real-Time Dimensional Measurement

Machine vision systems measure outside diameter, pitch, and length continuously while the cable is being produced. This allows manufacturers to:

- Maintain tight tolerances at full line speed

- Detect dimensional drift instantly

- Avoid costly rework and scrap

CORPEX CMVS systems achieve measurement accuracy down to ±0.002 inches while operating at production speeds

Early Defect Detection Before Scrap Is Created

Instead of discovering defects after production, machine vision identifies problems as soon as they appear. This includes:

- Out-of-spec diameter

- Irregular pitch or convolution

- Missing or misaligned copper tape

- Surface defects on ESP cables

Instant alarms allow operators to correct issues immediately, preventing defects from spreading down the line.

Machine Vision for Copper Taping Inspection

Copper taping is one of the most critical and defect-prone stages in cable manufacturing. Machine vision brings full process visibility by inspecting every revolution of the taping process.

Machine vision for copper taping enables:

- Real-time measurement of pitch, overlap percentage, and tape angle

- Detection of missing tape, loose tape, and misalignment

- Automatic logging of inspection data for traceability

CORPEX copper taping inspection systems capture high-resolution images of each wrap and calculate precise measurements while flagging deviations instantly Copper Taping.

Learn more about

Machine Vision for Copper Taping

Continuous Data Logging and Production Traceability

Machine vision systems do more than inspection. They create a complete digital record of production quality.

Benefits include:

- Automatic data logging for audits and certifications

- Trend analysis to identify recurring issues

- Improved process control and continuous improvement

CORPEX systems integrate directly with PLC, SCADA, MES, and OPC environments for automated reporting and alarms

Choosing the Right Machine Vision System for Your Line

Wire and cable manufacturers require different inspection capabilities depending on product size and application. CORPEX offers a full range of CMVS systems:

- CMVS 35 for small diameter cables up to 35 mm

- CMVS 55 for mid-range armored and convoluted cables

- CMVS 100 for high-volume production up to 100 mm

- CMVS 125 for large diameter and heavy-duty cable lines

Explore

Machine Vision for Wire & Cable

Industry 4.0 and Smart Manufacturing Impact

Machine vision plays a critical role in Industry 4.0 by enabling smarter, data-driven manufacturing. When integrated with industrial IT systems, machine vision helps manufacturers:

- Reduce downtime through predictive insights

- Improve quality consistency across shifts and plants

- Support digital transformation initiatives

Learn more about

Industrial IT & Automation

FAQ: Machine Vision in Wire and Cable Manufacturing

What problems does machine vision solve in wire and cable manufacturing

It detects defects early, ensures dimensional accuracy, reduces scrap, and provides full production traceability.

Can machine vision work at full production speed

Yes. CORPEX systems are designed to inspect continuously at line speed without slowing production.

Is machine vision suitable for armored and convoluted cables

Yes. CORPEX machine vision systems are specifically designed for armored and convoluted cable manufacturing.

Does machine vision support quality audits

Yes. All inspection data is logged automatically for audits, reporting, and troubleshooting.

Can machine vision integrate with existing automation systems

Yes. CORPEX systems integrate with PLC, SCADA, MES, and OPC environments.

Who Is CORPEX

CORPEX is a Canadian-based technology company specializing in machine vision systems, AI-driven inspection, and industrial automation solutions. With over 30 years of experience, CORPEX helps manufacturers improve quality, reduce waste, and modernize production through Industry 4.0 technologies.

Learn more about

CORPEX

Contact CORPEX

Phone: +1 (416) 358 0005

Email: getinfo@corpex.biz