Surface Defect Detection for ESP Cables

Hybrid AI and Vision for Armor Defect Detection

Surface Defect Detection for ESP Cables combines artificial intelligence and machine vision to detect armor deformation and puckering during cable manufacturing. This hybrid technology identifies variations in shape and compression as they occur, helping manufacturers maintain consistent product dimensions and prevent costly rework.

By using both vision and AI in parallel, CORPEX ensures reliable, real-time defect recognition that surpasses traditional single-technology inspection methods.

Core Features

Real-time

inspection of cable armor and geometry

Hybrid AI and vision

analysis for accurate classification

Early detection

of compression and interlocking errors

Integration

with CMVS and EMVS systems for full line coordination

Reduction

of false alarms through dual verification

Compatible

with SCADA, MES, and OPC environments

Understanding Puckering

Puckering occurs when an armored cable layer compresses unevenly, causing the cable to bulge or contract irregularly. The product may appear normal, but once tension is applied, the dimensional difference becomes visible.

If not detected early, puckering can lead to interlocking issues, reduced cable performance, and material waste. CORPEX addresses this by combining measurement precision with intelligent defect interpretation.

How the System Works

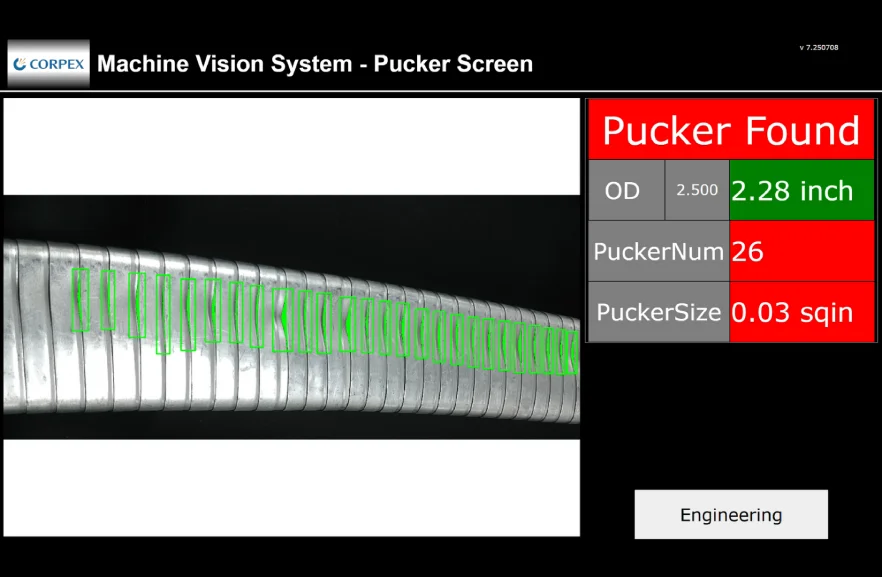

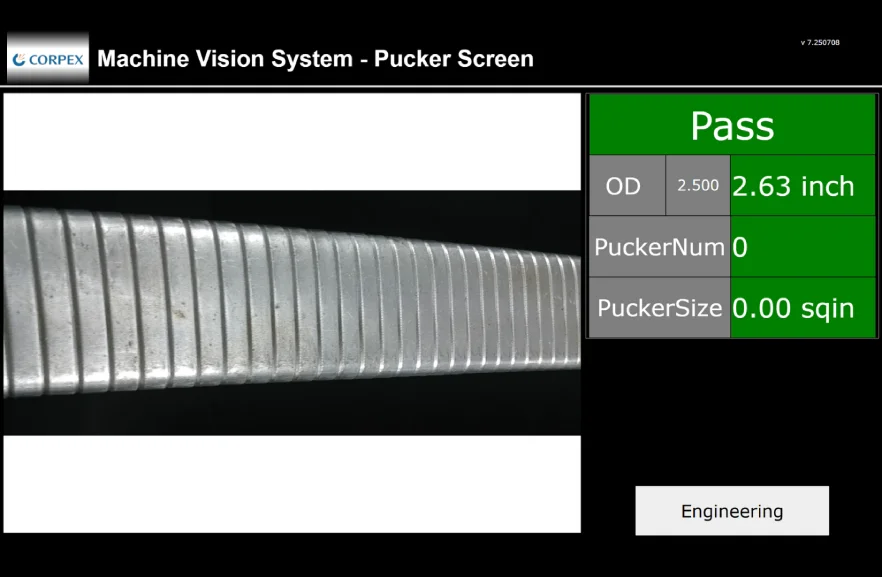

The Puckering Detection System uses stacked vision and AI algorithms to inspect the cable surface and detect shape deviations. Machine vision identifies potential irregularities, while the AI algorithm interprets these findings to confirm if the anomaly is a true defect or a harmless variation.

This collaboration between visual detection and AI reasoning eliminates both false positives and false negatives, ensuring only real quality concerns trigger operator attention.

Puckering Detection System

• Prevents rework and production downtime

• Improves accuracy of quality assurance processes

• Ensures consistent armor profile and cable structure

• Enables trend analysis and process refinement through stored inspection data

• Stores image and defect data for traceability and quality reporting

Applications

• ESP and armored cable production

• Communication and control cables

• Re-spooling or tension-controlled winding lines

• Any process where dimensional stability is critical

Puckering Detection System

• Prevents rework and production downtime

• Improves accuracy of quality assurance processes

• Ensures consistent armor profile and cable structure

• Enables trend analysis and process refinement through stored inspection data

• Stores image and defect data for traceability and quality reporting

Applications

• ESP and armored cable production

• Communication and control cables

• Re-spooling or tension-controlled winding lines

• Any process where dimensional stability is critical

SHARE ON SOCIAL MEDIA

DOWNLOAD THE PDF FILE FOR CABLE & WIRE MANUFACTURING

SHARE ON SOCIAL MEDIA

DOWNLOAD THE PDF FILE FOR CABLE & WIRE MANUFACTURING