Introduction to Machine Vision Building a Solid Foundation

In the era of Industry 4.0, characterized by the seamless integration of digital technologies into manufacturing and production processes, the convergence of Industrial A.I. and IoT has ushered in a new wave of innovation. In today’s fast-paced world, technology continues to evolve at an astonishing rate, revolutionizing industries and reshaping the way we work. Whether you’re in manufacturing, healthcare, automotive, or virtually any other sector, machine vision has the potential to transform your operations, enhance quality control, and boost efficiency.

What is Machine Vision?

At its core, machine vision is a field of artificial intelligence that enables computers to interpret and understand visual information from the world around us. Just as our eyes capture visual data that our brain processes to understand our environment, machine vision systems use cameras, optics, lighting, and sophisticated algorithms to perceive and make sense of images and videos.

The Components of Machine Vision

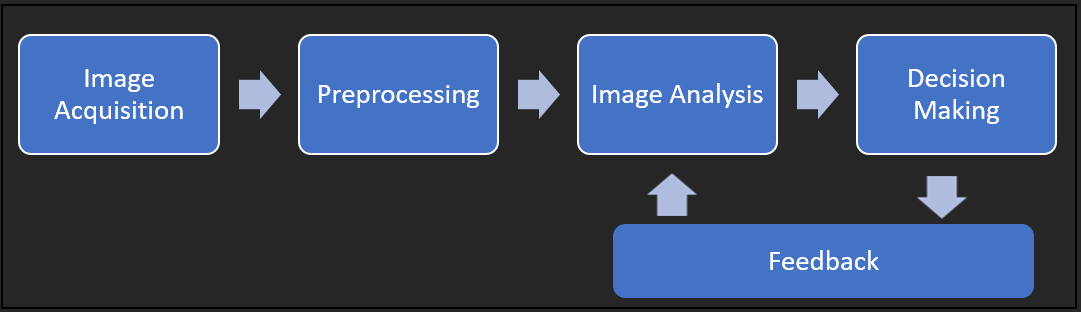

A typical machine vision system comprises several key components working harmoniously to extract meaningful information from visual data:

Image Acquisition: High-quality images are the foundation of machine vision. Cameras, sensors, and other imaging devices capture the visual input.

Preprocessing: Raw images are often noisy or contain irrelevant data. Preprocessing involves tasks like noise reduction, image enhancement, and calibration to ensure accurate analysis.

Image Analysis: This is where the magic happens. Advanced algorithms analyze the preprocessed images, detecting patterns, objects, shapes, and more.

Decision Making: Based on the analysis, the machine vision system makes decisions or triggers actions. For instance, in manufacturing, it might identify defective products and remove them from the production line.

Feedback Loop: Many machine vision systems provide real-time feedback to improve accuracy. They learn from their mistakes, refining their analyses over time.

The Importance of Machine Vision

Machine vision is not just about automating processes; it’s about elevating the way we approach complex tasks. Here are some compelling reasons why machine vision has become an indispensable tool across industries:

Precision and Accuracy

Machine vision systems excel at tasks that require meticulous precision and unfaltering accuracy. From measuring dimensions to detecting minuscule defects, their consistent performance surpasses human capabilities.

Efficiency and Speed

Imagine a manufacturing line where products are inspected with lightning speed, and deviations are flagged instantly. Machine vision systems operate at remarkable speeds, enhancing productivity and reducing bottlenecks.

Quality Control

Maintaining consistent product quality is essential for brand reputation. Machine vision systems ensure that every product meets predefined quality standards, reducing the chances of faulty items reaching customers.

Cost Savings

By automating tasks that were traditionally labor-intensive, machine vision reduces the need for manual labor. This not only leads to cost savings but also minimizes human errors that can lead to expensive recalls or rework.

In the coming articles of this series, we’ll delve deeper into the world of machine vision, exploring its applications, benefits, challenges, and even glimpses of its future potential. We invite you to join us on this journey as we unravel the fascinating realm of technology that is shaping the future of industries worldwide.