CMVS

Real-Time Measurement for Armored and Convoluted Products

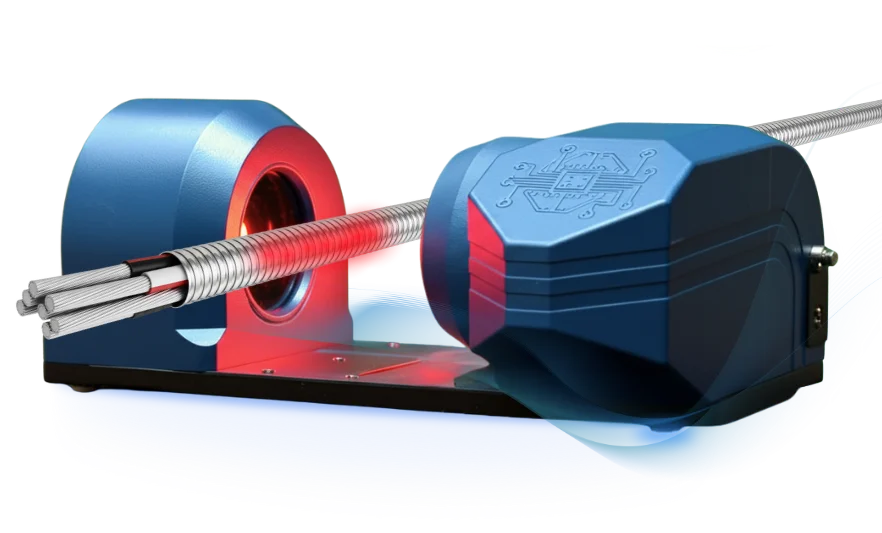

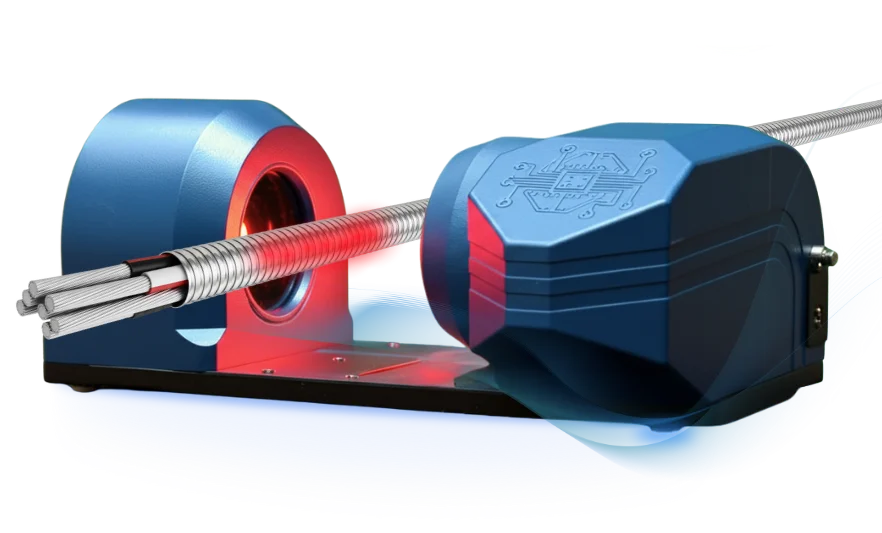

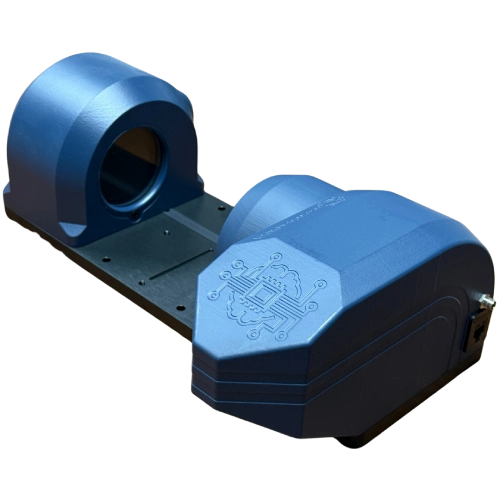

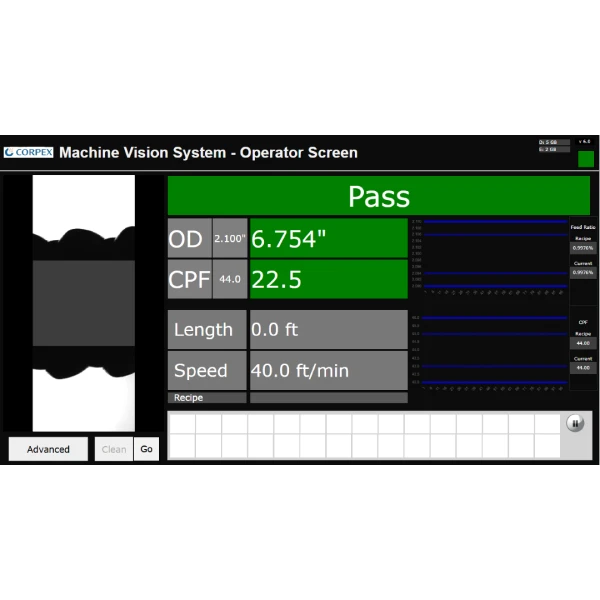

The CORPEX Machine Vision System (CMVS) is designed to deliver precise, real-time measurement and defect detection for armored and convoluted cable manufacturing. By combining high-speed imaging with AI-based analysis, CMVS measures outside diameter, convolution pitch, and product length while maintaining exceptional accuracy and consistency.

Its advanced vision and data processing capabilities help manufacturers ensure product integrity, improve quality control, and minimize production waste.

Core Features

High-speed

Real-time measurement up to 80 ft/min

Live visual feedback

with alarms for out-of-spec conditions

Accuracy

of ±0.001–0.002 inches depending on model

Data storage

and image library for quality assurance

Detection of dimensional

deviations and surface anomalies

Integration with

PLC, SCADA, MES, and OPC environments with 19.5-inch touchscreen display

How CMVS Works?

CMVS captures and analyzes the product profile in real time using multiple high-resolution sensors. It compares every reading against target parameters received from the production system and highlights any deviations.

All measurement data is logged for traceability and analysis, allowing engineers and operators to review product consistency, identify trends, and refine production parameters for ongoing improvement.

Applications

• Armored cable manufacturing

• Control and communication cables

• Re-spooling and take-up measurement

• Dimensional inspection for convoluted or wrapped products and more

Product Range

• Target OD range: 0.15–1.35 inches

• Accuracy: ±0.001 inches in real time at max speed of armoring line up to 80ft/min

• Max pitch: 0.65 inches (18 convolutions per foot)

• Flexible mounting with 19.5-inch touchscreen display

• Optional smart light

• Target OD range: 0.25–2.2 inches

• Accuracy: ±0.002 inches in real time at max speed of armoring line up to 80ft/min

• Max pitch: 0.75 inches (16 convolutions per foot)

• Flexible mounting

• 19.5-inch touchscreen interface

• Optional smart light

• Target OD range: 0.25–4.0 inches

• Accuracy: ±0.002 inches in real time at max speed of armoring line up to 80ft/min

• Max pitch: 0.75 inches (16 convolutions per foot)

• Designed for high-speed armoring lines up to 80 ft/min

• Optional smart light

• Target OD range: 0.25–5.0 inches

• Accuracy: ±0.002 inches in real time at max speed of armoring line up to 80ft/min

• Max pitch: 0.75 inches (16 convolutions per foot)

• Includes live visual feedback and quality data logging

• Optional smart light

• Designed for flat and control cable

• Major axis: 1.5–5.0 inches

• Minor axis: 0.24–1.25 inches

• Accuracy: ±0.002 inches in real time at max speed of armoring line up to 80ft/min

• Measures both width and height simultaneously for advanced dimensional control

• Optional smart light

Industry 4.0 Ready

CMVS connects directly with other CORPEX vision and AI systems, enabling a complete smart inspection network across production lines. It forms a key part of the Industry 4.0 transformation by providing measurable, actionable insights at every stage of manufacturing.

See CORPEX in Action

High-Precision Inspection for Small-Diameter Cable

Engineered for compact applications, CMVS 35 delivers ±0.001″ accuracy in real time. Ideal for fine-gauge armored cable.

SHARE ON SOCIAL MEDIA

DOWNLOAD THE PDF FILE FOR CABLE & WIRE MANUFACTURING

SHARE ON SOCIAL MEDIA

DOWNLOAD THE PDF FILE FOR CABLE & WIRE MANUFACTURING